Exploring the Importance of Packing Optimisation in the UK

What Significance Does Efficient Packing Hold in UK Logistics?

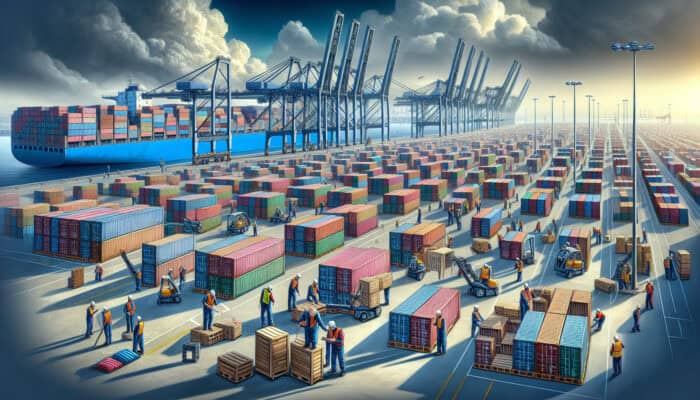

Packing Optimisation Tips for Clearance: Efficient packing is fundamental to the UK logistics framework, especially for adhering to the specific criteria set by UK customs. By ensuring goods are packed efficiently, companies can significantly reduce delays and costs associated with the clearance process. Approximately 40% of UK businesses have reported shorter clearance times after adopting optimised packing techniques. A notable example is the Port of Felixstowe, recognised as the UK’s busiest container port. Here, advancements in packing optimisation have not only streamlined operations but also enabled faster shipment turnaround. The strategic arrangement of items within shipping containers not only complies with customs regulations but also optimises space usage, thereby enhancing operational efficiency.

In addition to customs compliance, efficient packing is important for maximising warehouse space utilisation. This aspect is increasingly vital as demand for warehouse space continues to escalate. Employing effective packing strategies enables businesses to store more items without sacrificing accessibility, thereby improving inventory management. For instance, a logistics provider located in the Midlands reported a 15% increase in storage capacity after implementing advanced packing optimisation techniques. This innovative approach minimises the need for additional warehouse space, resulting in cost savings and improved profitability.

How Do UK Regulations Shape Packing Techniques?

UK regulations significantly influence packaging practices, primarily through stringent guidelines on labelling, materials, and hazardous substance management. Adhering to these regulations is crucial for businesses aiming to avoid substantial fines and ensure seamless operations. The introduction of post-Brexit standards has added complexity to these regulations, compelling UK businesses to adjust their packing strategies accordingly.

To effectively navigate this regulatory landscape, businesses can undertake several proactive measures. First and foremost, conducting comprehensive research into the current UK trade guidelines is essential. This entails staying informed about any regulatory changes and ensuring all packing methods comply with the latest standards. Additionally, companies should invest in specialised training for their packing teams to ensure each member understands the specific requirements set by UK customs. This training may encompass correct labelling practices and the appropriate use of approved materials for packing hazardous goods.

Incorporating a robust quality control process is another critical step. Regular audits of packing procedures can identify non-compliance areas before they escalate into significant issues. By making these necessary adjustments, businesses not only comply with regulations but also streamline their processes to expedite clearance, reducing the risk of delays that could adversely affect their profit margins.

What Key Materials Support Sustainable Packing in the UK?

Sustainable packing materials are increasingly vital within the UK, serving not only to meet compliance requirements but also to bolster brand reputation and attract eco-conscious consumers. The transition towards eco-friendly alternatives, such as recyclable cardboard and biodegradable packing peanuts, is prevalent across UK supply chains. This shift towards sustainability not only promotes optimisation but also reduces environmental impact and costs.

Numerous UK firms have reported a 25% reduction in waste by adopting sustainable packing practices, contributing to both efficiency and cost savings. For example, a leading London-based retailer transitioned to 100% recyclable packaging for shipping and observed a marked improvement in its waste management metrics. This practice not only aligns with consumer expectations but also helps businesses meet UK government initiatives to reduce plastic use.

Moreover, utilising materials sourced from local suppliers can substantially lessen the carbon footprint associated with packing. By prioritising local over imported materials, companies can support the UK economy while achieving faster turnaround times and lower shipping costs. In addition, businesses should consider implementing a take-back program for packaging materials, encouraging customers to return used packaging for recycling or repurposing. This approach fosters a circular economy, enhancing sustainability and promoting brand loyalty among environmentally aware consumers.

How Is Technology Transforming Packing Optimisation in the UK?

The emergence of advanced technologies has dramatically reshaped packing optimisation within the UK logistics sector. Innovations such as artificial intelligence (AI) and automation are driving this transformation, improving packing efficiency and precision. UK companies have reported up to a 30% increase in efficiency after integrating these technologies into their logistics operations.

AI algorithms can analyse large datasets to identify the most efficient packing configurations for different products, accounting for factors such as weight, fragility, and size. For instance, a logistics firm in Manchester used AI to refine its packing process, resulting in reduced material usage and improved space utilisation in containers. This not only lowers costs but also reduces processing times, enabling faster port clearance.

Additionally, automation plays an essential role in minimising human error during the packing process. Automated packing machines can consistently apply the required amount of material and ensure items are securely packed, thereby enhancing product integrity during transit. Furthermore, these machines can operate at speeds exceeding those of human workers, significantly boosting productivity metrics. Companies adopting automated packing solutions have reported faster turnaround times and lower damage rates, aligning with the broader trend of digital transformation in the UK logistics industry.

What Are the Best Practices for Packing Optimisation in UK Warehouses?

Implementing best practices for packing optimisation in UK warehouses is crucial for maximising space and resources. One effective strategy is just-in-time (JIT) packing, which ensures that items are packed only as needed rather than in bulk. This method minimises waste and enhances supply chain resilience, allowing businesses to adapt swiftly to fluctuating demand. Many companies have reported improved profitability by implementing JIT practices, which reduce excess inventory and storage costs.

Inventory management also plays a pivotal role in effective packing optimisation. By employing inventory management software, companies can monitor stock levels in real time, ensuring that packing operations align with actual demand. This alignment reduces the risk of over- or underpacking, both of which can lead to delays and increased costs. For instance, a logistics provider in Birmingham has successfully integrated inventory management systems that deliver real-time data, enabling it to optimise its packing operations significantly.

Furthermore, training personnel on packing best practices is vital. Employees should be well-versed in techniques that enhance packing efficiency, such as proper weight distribution and the use of appropriate packing materials. By fostering a culture of continuous improvement and training, companies can guarantee that their packing processes remain effective and compliant with UK regulations. Ultimately, these best practices not only reduce costs but also streamline and strengthen the supply chain.

Essential Strategies for Clearance Packing in the UK

What Are the Best Practices for Weight Distribution in UK Warehouses?

Effective load balancing, in accordance with UK health and safety guidelines, is vital to preventing damage during transportation. Proper weight distribution guarantees that items arrive at clearance points intact, minimising the risk of accidents and delays. In UK warehouses, it is crucial to utilise pallets, which are standard in distribution centres, to facilitate this process.

When packing items, companies should consider several key advantages of effective weight management in UK contexts, including:

- Enhanced safety during transport and handling.

- Reduced risk of product damage and associated costs.

- Improved compliance with UK health and safety regulations.

- Increased efficiency in loading and unloading operations.

Effective weight distribution involves positioning heavier items at the base of the pallet and lighter items on top, thereby creating a stable load. This method prevents tipping during transit and ensures an even weight distribution. Additionally, workers should be trained to identify when a load is improperly balanced, as this can lead to significant inefficiencies and potential hazards.

Moreover, using technology such as weight sensors can provide real-time feedback on load distribution, enabling adjustments before dispatch. By incorporating these practices into warehouse operations, companies can enhance overall safety and efficiency, ensuring their packing processes comply with UK logistics standards.

What Factors Affect Packing Density Under UK Standards?

Packing density is a crucial factor in logistics, particularly when complying with UK storage standards. Maximising container usage not only accelerates clearance at ports such as Dover but also delivers significant cost savings for companies. By optimising packing density, businesses can achieve up to a 30% increase in capacity, facilitating a more efficient utilisation of transport and storage resources.

Several factors influence packing density, including product size and shape, as well as the type of packaging materials employed. For instance, using modular packaging can help businesses maximise space by enabling uniform stacking and arrangement of items. Additionally, companies should consider the dimensions of shipping containers and how to utilise every available inch of space best.

Training staff on packing configurations that enhance density is also essential. Employees should be knowledgeable about the most efficient methods for arranging products within containers, taking into account factors such as weight distribution and fragility. Implementing a systematic packing approach not only optimises space but also ensures compliance with transportation regulations, thereby minimising the risk of customs delays.

Finally, technology can help maximise packing density. Software solutions that simulate packing arrangements can help companies identify the most efficient layouts before packing goods. This proactive strategy ensures businesses remain competitive in the UK logistics market while optimising resource use.

What Common Packing Tools Are Recommended in the UK?

Utilising appropriate packing tools is essential to enhance security and ensure compliance with UK local regulations governing goods transport. Items such as strapping, void fillers, and corner protectors are readily available from UK suppliers and play a significant role in maintaining product integrity throughout customs clearance.

Strapping is vital for securing packages during transit, preventing shifting and damage. Various strapping materials, including polypropylene and polyester, can be selected based on the weight and fragility of the items being shipped. Additionally, void fillers such as bubble wrap and biodegradable packing peanuts can be employed to fill empty spaces within boxes, providing extra cushioning and protection for delicate items.

Furthermore, corner protectors help safeguard product edges, particularly during stacking or transport. This is especially crucial for items that are easily damaged or possess sharp edges. By incorporating these tools into packing operations, businesses can significantly reduce the risk of product damage, align with UK regulations, and enhance their market reputation.

Additionally, companies should consider investing in packing tape dispensers and labelling tools to streamline the packing process. Having the right tools readily available not only expedites operations but also ensures that all packages are correctly labelled for customs, thereby minimising the chances of delays. By utilising these common packing tools, UK businesses can improve their packing processes, ensuring compliance and enhancing overall efficiency.

What Is the Process for Packing Optimisation in the UK?

How to Prepare Goods for UK Customs Clearance?

Preparing goods for UK clearance requires a systematic approach to packing optimisation that evaluates item sizes against UK import regulations. This meticulous process can effectively halve processing times, ensuring compliance with national standards and facilitating smoother operations.

The initial step in this process is to conduct a comprehensive assessment of the goods designated for shipment. Companies should carefully evaluate the dimensions, weight, and fragility of each item, as UK customs regulations dictate specific requirements for different product types. By categorising items accordingly, businesses can tailor their packing strategies to meet these stipulations, ensuring that all products are packed correctly to avoid delays.

Subsequently, businesses should develop a packing plan outlining the most effective methods for packing each item category. This plan must account for the required packaging materials and the most efficient arrangement of items within shipping containers. Involving team members in this planning process can foster innovative solutions and enhance overall compliance with UK regulations.

Lastly, implementing a robust quality control mechanism is imperative. Regular inspections of packed items help ensure compliance with all necessary clearance criteria, preventing potential customs issues. By adhering to this structured process, businesses can optimise their packing operations, resulting in faster clearance times and improved efficiency in the UK market.

What Role Does Technology Play in Enhancing Packing in the UK?

Integrating technology is vital for enhancing packing processes within the UK. Using UK-based software tools can help ensure accurate volume calculations, improving precision and efficiency in line with local logistics trends. Many firms have adopted these advanced tools to streamline their packing operations, resulting in increased productivity and reduced errors.

One of the primary advantages of incorporating technology into packing processes is the ability to automate volume calculations. This automation eliminates manual errors that frequently occur during packing and ensures compliance with UK regulations on weight and size limits. For instance, a logistics company in Liverpool implemented a software solution that calculates optimal packing configurations based on item dimensions and weights, resulting in a noticeable reduction in material costs and faster clearance times.

Moreover, utilising inventory management systems can provide real-time data on stock levels, enabling businesses to respond swiftly to changes in demand. By integrating these technologies, firms can optimise their packing processes, ensuring they are prepared for fluctuations in consumer behaviour and market conditions.

Training staff to use these tools effectively is also crucial. Ensuring that employees possess the necessary skills to operate packing software helps maintain high levels of accuracy and efficiency. By cultivating a tech-savvy workforce, UK businesses can position themselves at the forefront of logistics innovation, enhancing their competitive edge in the marketplace.

Why Do Packing Failures Occur During UK Inspections?

Packing failures during UK inspections often stem from overlooked details, particularly regarding labelling laws and packaging standards. Understanding these potential pitfalls is essential for businesses aiming to refine their clearance strategies.

One common cause of packing failures is inadequate or incorrect labelling. UK customs regulations stipulate precise information on package contents, including country of origin, weight, and handling instructions. Failing to comply with these regulations can lead to significant delays and complications at customs, undermining overall optimisation efforts. Businesses should ensure that all labels are clear, accurate, and compliant with UK standards to avoid such issues.

Another contributing factor to inspection failures is the use of non-compliant packing materials. The UK has specific requirements regarding the types of materials permissible for packaging, particularly for hazardous goods. Non-compliance with these regulations can result in fines and delays, adversely affecting a company’s reputation and financial outcomes.

Regular compliance training for packing teams can mitigate these risks. By educating employees on the importance of adhering to UK customs regulations and proper packing techniques, businesses can significantly reduce the likelihood of inspection failures. Furthermore, implementing a pre-shipment checklist that includes compliance verifications can help ensure all packages meet required standards before leaving the warehouse, facilitating smoother clearance.

What Are the Advantages of Cost-Effective Packing Strategies in the UK?

Employing cost-effective packaging strategies delivers significant benefits for UK businesses, particularly by reducing shipping and logistics costs. Techniques such as modular packaging and bulk shipping align with current UK economic trends and can reduce costs by 20-30%.

Modular packaging enables companies to design their packaging to maximise space efficiency. This method not only diminishes the volume of materials utilised but also optimises the amount of product that can be shipped in a single load, thus reducing shipping costs. For example, a Birmingham-based manufacturer adopted modular packaging and reported substantial savings in transport costs by dispatching more products per journey, resulting in fewer trips and lower fuel costs.

Bulk shipping is another strategy that can yield significant savings. By consolidating shipments and minimising delivery frequency, businesses can decrease overall logistics costs. This approach is particularly advantageous for UK exporters who frequently face high shipping fees. Through strategic shipment planning and combining multiple orders, companies can achieve greater economies of scale.

Moreover, these cost-saving strategies are not solely about reducing expenses; they also enhance efficiency and productivity within the supply chain. By streamlining packing processes and minimising waste, businesses can allocate resources more effectively, thereby enhancing profitability. As UK firms continue to navigate a competitive landscape, embracing cost-effective packing strategies is vital for long-term success.

Expert Recommendations on Packing Optimisation for Clearance

What Advanced Techniques Address UK-Specific Challenges?

Tailoring packing strategies to address UK-specific challenges, particularly weather conditions, is essential to protect goods during transit. The UK’s unpredictable climate can lead to moisture exposure, which can adversely affect product integrity. Experts recommend using moisture-resistant materials to protect against potential damage, which can speed clearance and improve customer satisfaction.

For instance, a food exporter based in Scotland encountered challenges with moisture-sensitive products. By transitioning to moisture-resistant packaging, they significantly curtailed spoilage during transit, resulting in enhanced clearance times and positive customer feedback. Utilising materials such as moisture barrier films not only safeguards products but also aligns with sustainability objectives, reducing waste from damaged goods.

Additionally, incorporating temperature-controlled packing solutions can bolster the preservation of sensitive items. For example, using insulated packaging for temperature-sensitive shipments ensures that products remain within required temperature ranges, preventing quality degradation. This practice is increasingly relevant for businesses dealing with perishable goods, where maintaining freshness is paramount.

Furthermore, training staff to identify and mitigate weather-related risks during packing can further enhance outcomes. Employees should be cognisant of the specific challenges posed by the UK climate and equipped with strategies for proactively resolving issues. By adopting these advanced techniques, businesses can refine their packing processes and guarantee smoother clearance amidst UK-specific challenges.

What Custom Solutions Aid High-Volume UK Exporters?

High-volume UK exporters often require tailored packing solutions to meet their specific requirements, minimising errors and improving efficiency. Implementing customised packing strategies can streamline operations and enhance productivity, ensuring that goods are prepared for clearance without unnecessary delays.

One effective approach is to establish standardised packing protocols tailored to the types of products being exported. For example, a London-based fashion retailer developed packing guidelines for its clothing shipments, including size-specific boxes and protective materials. This practice not only reduced packing time but also minimised the risk of damage during transport.

Additionally, investing in advanced packing machinery can enhance packing speed and consistency. High-volume exporters can benefit from automated packing lines that adapt to diverse product types, ensuring efficient packing while maintaining quality standards. By leveraging technology, businesses can reduce labour costs and improve packing accuracy, contributing to timely deliveries.

Moreover, maintaining open communication with logistics partners is essential. High-volume exporters should collaborate closely with shipping companies to ensure that packing practices align with shipping requirements. This cooperation can enhance efficiency by enabling logistics partners to share best practices based on their experience.

By implementing these custom solutions, high-volume UK exporters can optimise their packing processes, reduce errors, and enhance overall efficiency, ensuring that they remain competitive in the global market.

How to Evaluate Long-Term Benefits in the UK Context?

Long-term evaluations of optimised packing strategies reveal substantial cost savings and operational improvements for UK businesses. For instance, companies that invest in sustainable packaging solutions often experience lower material costs and enhanced brand reputation, leading to sustained improvements in profitability.

A leading electronics manufacturer in the Midlands adopted optimised packing techniques and reported a 15% reduction in packaging costs over two years. This strategy not only reduced costs but also bolstered their corporate image, as consumers increasingly favour brands that prioritise sustainability. This dual benefit illustrates how optimised packing can yield long-term advantages in both cost management and brand loyalty.

Furthermore, businesses that implement robust packing processes tend to experience fewer supply chain disruptions. By ensuring compliance with UK regulations and upholding high packing standards, companies can avoid costly delays and penalties, which contribute to smoother operations. For example, a logistics firm that invested in packing optimisation reported a decrease in customs-related hold-ups, resulting in improved cash flow and customer satisfaction.

Finally, consistently monitoring and refining packing practices can lead to ongoing improvement. By regularly evaluating packing processes, businesses can identify opportunities for further optimisation, ensuring they remain competitive in the dynamic UK market. The long-term benefits of packing optimisation are evident: enhanced efficiency, reduced costs, and improved customer relations.

What Are the Key Benefits of Optimisation?

How Does It Reduce Costs for UK Operations?

Packing optimisation is instrumental in minimising costs for UK operations by reducing wasted space in shipments, thereby accelerating clearance times and improving profitability. By implementing effective packing strategies, businesses can achieve notable savings, with many UK companies seeing shipping cost reductions of up to 20%.

One of the primary ways packing optimisation reduces costs is by improving space utilisation. By ensuring products are packed efficiently, companies can maximise the number of items per container, reducing the total number of shipments required. This not only curtails transportation expenses but also diminishes emissions, contributing to sustainability objectives.

Additionally, optimised packing lowers the risk of product damage during transit. When items are appropriately secured and packed, the likelihood of breakage or spoilage diminishes significantly. This reduction in damages translates to decreased replacement costs and improved customer satisfaction, as clients receive their products in excellent condition.

Moreover, packing optimisation can facilitate better inventory management. By utilising strategies such as just-in-time packing, businesses can reduce excess inventory costs, freeing up capital for other critical operations. This comprehensive approach to cost management helps companies remain competitive in the UK market while enhancing overall efficiency.

How to Measure Success in UK Packing Scenarios?

Measuring success in UK packing scenarios necessitates tracking specific metrics that provide clear insights into the effectiveness of packing processes. Key performance indicators (KPIs) such as clearance speed, cost savings, and customer satisfaction can offer valuable data for businesses aiming to refine their operations and achieve measurable improvements.

Clearance speed ranks as one of the most vital metrics to monitor. By analysing the time taken for packages to clear customs, companies can identify bottlenecks and areas requiring enhancement. Implementing optimised packing strategies often leads to faster clearance times, enabling businesses to respond promptly to customer demand.

Cost savings represent another crucial metric. Companies should routinely evaluate their packaging costs, comparing them with historical data to assess the effectiveness of their optimisation efforts. By documenting cost reductions, businesses can justify further investments in packing technology and processes.

Furthermore, customer satisfaction surveys can provide insights into how packaging practices affect the overall customer experience. Positive feedback on product condition upon arrival can indicate effective packing, while complaints may highlight areas for improvement. By focusing on these metrics, UK businesses can continually refine their packing processes, ensuring they achieve measurable gains in efficiency and profitability.

What Impact Does Packing Optimisation Have on UK Supply Chain Reliability?

Enhanced packing practices significantly influence supply chain reliability across the UK, strengthening the integrity of logistics operations and minimising disruptions caused by customs holds. By optimising packing processes, businesses can ensure timely deliveries and maintain a steady flow of goods, which is essential for sustaining customer satisfaction and trust.

One notable advantage of optimised packing is the decreased incidence of customs-related delays. When goods are packed in accordance with UK regulations, the likelihood of inspections and holds diminishes. This streamlined approach not only boosts efficiency but also fosters customer confidence in timely deliveries.

Moreover, improved packing practices enhance inventory management. By ensuring that items are packed efficiently and securely, businesses can avert stockouts and backorders, which can disrupt the supply chain. This proactive strategy enables companies to sustain optimal inventory levels, ensuring they can meet customer demands without unnecessary delays.

Furthermore, enhanced reliability cultivates stronger relationships with suppliers and logistics partners. When businesses consistently demonstrate sound packing and delivery processes, they build trust with their partners, facilitating smoother collaborations and improved overall supply chain performance. By concentrating on packing optimisation, UK companies can markedly enhance their supply chain reliability, ultimately contributing to long-term success.

Research-Backed Benefits of Packing Optimisation Tips for Clearance

What Proven Methods Enhance UK Compliance?

Research indicates that evidence-based packing methods can significantly improve compliance with UK laws, helping businesses avoid penalties and streamline their procedures. By employing strategies that align with regulatory requirements, companies can mitigate risks associated with customs inspections and enhance their overall operations.

One proven approach is to adopt standardised packing protocols that comply with UK regulations. For example, businesses can implement templates for packing lists and labels that comply with customs requirements, reducing the potential for errors. By employing these standardised practices, companies can improve their compliance rates and expedite the clearance process.

Moreover, training staff on the importance of adhering to compliance standards is crucial. Regular workshops and training sessions can ensure employees are well informed about the latest UK regulations, helping prevent costly packing mistakes. By fostering a culture of compliance within the organisation, businesses can cultivate greater accountability and commitment to meeting regulatory requirements.

Additionally, leveraging technology to monitor compliance can yield significant advantages. Software solutions that track packing standards and flag non-compliance issues can help businesses stay ahead of potential challenges. By integrating these tools into daily operations, companies can enhance compliance and streamline packing processes, ultimately improving clearance times and reducing costs.

What Long-Term Advantages Do UK Businesses Experience?

The long-term benefits of packing optimisation for UK businesses extend beyond immediate cost savings; they also enhance sustainability and efficiency. By embracing optimised packing practices, companies can foster a culture of continuous improvement, ultimately bolstering their competitiveness in the market.

A significant long-term advantage is the reduction of waste associated with packaging materials. By adopting sustainable packaging solutions, businesses can reduce their environmental impact and improve their reputation with eco-conscious consumers. For instance, a cosmetics brand in the UK switched to biodegradable packaging and saw an increase in customer loyalty, demonstrating how sustainable practices can drive lasting success.

Moreover, firms that prioritise packing optimisation frequently experience improvements in operational efficiency. Streamlined packing processes lead to faster turnaround times and higher productivity, enabling companies to respond swiftly to market demands. This adaptability is crucial in today’s fast-paced business environment, where consumer preferences are in constant flux.

Finally, long-term investments in packing optimisation can enhance financial stability. As businesses decrease costs and improve efficiency, they can allocate resources more effectively, ensuring sustained growth and sustainability. By focusing on packing optimisation as a core strategy, UK companies can secure their position in increasingly competitive markets.

How to Integrate Findings into Daily UK Practices?

Incorporating research-backed packing optimisation tips into daily practices is essential to improve packing routines and ensure compliance with UK regulations. Real-world examples from industry reports underscore the effectiveness of these strategies and offer practical applications for businesses seeking to enhance their operations.

For instance, a logistics provider in London implemented best practices informed by industry research, resulting in a 30% reduction in customs delays. By adopting standardised packing protocols and employing technology to monitor compliance, they significantly streamlined their processes. This example illustrates how businesses can leverage research insights to enhance their packaging operations.

Additionally, regular training sessions grounded in research findings can promote a culture of continuous improvement within organisations. Companies that prioritise ongoing education for their packing teams are better equipped to adapt to regulatory changes and evolving consumer expectations. This proactive approach not only enhances compliance but also contributes to overall operational efficiency.

Incorporating research-derived metrics and KPIs can also facilitate the evaluation of packing processes. By monitoring performance data over time, businesses can identify areas for improvement and make data-driven decisions. This evidence-based methodology ensures that packing optimisation remains a priority for ongoing success and aligns with the evolving UK logistics landscape.

What Economic Benefits Arise from Research on Packing Optimisation?

Research on packing optimisation has shown substantial economic benefits for UK businesses, demonstrating how effective packing practices can reduce costs and improve profitability. Evidence from British economic reports indicates the potential for significant savings, improved cash flow, and long-term financial stability in the clearance industry.

One of the primary economic benefits is the reduction of transportation costs associated with efficient packing. Studies indicate that businesses employing optimised packing strategies can realise up to 25% savings in shipping expenses. For instance, a UK-based manufacturer implemented streamlined packing methods, resulting in fewer shipments and lower freight costs, ultimately boosting their bottom line.

Moreover, optimised packing can improve cash flow by expediting clearance. By ensuring compliance with UK regulations and minimising delays, businesses can maintain a steady revenue stream and reduce the risk of cash-flow disruptions. This financial stability allows companies to reinvest in their operations and drive growth.

Additionally, research suggests that companies prioritising packing optimisation are more likely to foster stronger relationships with customers and suppliers. By demonstrating consistent packing practices, businesses can build trust and loyalty among stakeholders, paving the way for long-term success in a competitive market. The economic advantages of packing optimisation are clear, making it an essential component of modern supply chain management in the UK.

Why Is Packing Optimisation Crucial for UK Businesses?

What Challenges Does It Address in the UK?

Packing optimisation directly addresses several critical challenges for UK businesses in the logistics sector, particularly in customs compliance and operational efficiency. Varying regional regulations can complicate the clearance process, requiring businesses to adopt tailored packing strategies to ensure compliance with local standards.

One of the primary challenges is navigating the complexities of UK customs regulations, which vary by product type and origin. Packing optimisation helps businesses align their packing practices with diverse regulations, ensuring smoother clearance and operational flow across the UK. This adaptability is crucial for maintaining efficient logistics operations, especially for companies managing a wide array of product lines.

Moreover, packing optimisation tackles the challenge of safeguarding product integrity during transit. Ensuring goods are properly packaged can prevent damage, reduce the risk of costly returns, and enhance customer satisfaction. By prioritising packing optimisation, UK businesses can directly address these challenges, ultimately improving operational efficiency and reducing costs.

Additionally, packing optimisation helps companies stay ahead of market demands. As consumer preferences evolve, businesses that can swiftly adapt their packaging strategies are better positioned to meet customer expectations, fostering loyalty and driving growth. By addressing these challenges through effective packing practices, UK businesses can ensure long-term success in a competitive environment.

What Are the Key Reasons for Adopting These Tips in the UK?

Implementing packing optimisation tips offers numerous advantages for UK businesses, enhancing their competitiveness and operational efficiency. Here are key reasons tailored to UK contexts that underscore the importance of these strategies:

- Improved compliance with UK customs regulations.

- Reduced shipping costs through enhanced space utilisation.

- Minimised risk of product damage during transit.

- Increased customer satisfaction and loyalty through timely deliveries.

By adopting these tips, businesses can traverse the complexities of UK logistics more effectively. Enhanced compliance ensures smoother clearance processes, diminishing the likelihood of costly delays and penalties. This proactive approach not only boosts operational efficiency but also improves financial performance.

Furthermore, optimising packing methods can deliver significant cost savings, enabling businesses to allocate resources more efficiently. Reducing product damage during transit enhances brand reputation, as customers are more inclined to return to businesses that consistently deliver goods in excellent condition.

Lastly, timely deliveries enhance customer satisfaction and loyalty, reinforcing a positive brand image in the highly competitive UK market. By implementing packing optimisation tips, businesses can ensure they remain agile and responsive to shifting consumer demands, ultimately contributing to long-term success.

How Can Businesses Stay Ahead in UK Logistics Trends?

Staying ahead in UK logistics trends necessitates a proactive approach to packing optimisation that adapts to evolving market demands and regulatory standards. Companies that prioritise innovation and invest in the latest packing technologies are better positioned to maintain their competitive edge within the logistics landscape.

One effective strategy is to remain informed about emerging technologies that can enhance packing processes, such as automation and artificial intelligence. By integrating these technologies into their operations, businesses can elevate efficiency, reduce errors, and streamline their packing workflows. For example, a logistics provider in Manchester adopted AI-driven packing solutions, resulting in a significant reduction in processing times and improved accuracy.

Furthermore, regularly reviewing industry best practices and adapting them to local market conditions is crucial. Engaging with industry associations and participating in training seminars can provide valuable insights into the latest trends and innovations. Companies that actively seek opportunities for learning and collaboration are better equipped to respond to changes in the logistics landscape.

Another vital aspect of staying ahead is fostering a culture of continuous improvement within the organisation. Encouraging employee feedback and regularly assessing packing processes can uncover areas ripe for optimisation. By remaining agile and adaptable, UK businesses can navigate the ever-changing logistics environment, ensuring they remain competitive and relevant in the market.

What Is the Impact of Sustainable Packaging on UK Businesses?

Optimising packing for sustainability is imperative for UK firms, particularly as they face increasing pressure to meet stringent environmental regulations and consumer expectations. Sustainable packaging practices not only help reduce carbon footprints but also enhance brand reputation and long-term profitability in a competitive domestic market.

Implementing sustainable packaging solutions, such as using eco-friendly materials and minimising packaging waste, can significantly reduce a company’s environmental footprint. For instance, businesses that adopt biodegradable packing products often receive positive feedback from customers who prioritise sustainability in their purchasing decisions. This alignment with consumer values can result in increased sales and customer loyalty.

Moreover, sustainable packing practices can lead to cost savings over time. By reducing material usage and minimising waste, companies can lower packing costs. For example, a retailer in London that transitioned to minimalist packing designs reported a 20% reduction in packaging costs, thereby enhancing profitability while upholding sustainability goals.

Additionally, adopting sustainable practices can help companies comply with evolving regulations. The UK government has implemented various initiatives to reduce plastic use and promote eco-friendly practices. By proactively adopting sustainable packaging methods, businesses can ensure compliance and position themselves as leaders in corporate responsibility.

Ultimately, optimising packing for sustainability not only benefits the environment but also enhances brand perception, drives customer loyalty, and contributes to long-term financial success within the UK market.

How to Implement These Tips Effectively in the UK?

What Initial Steps Are Necessary for UK-Based Packing Overhauls?

Effectively implementing packing optimisation strategies in the UK commences with a comprehensive review of current practices against local guidelines. This initial assessment lays the groundwork for a successful overhaul, ensuring all packing processes comply with UK regulations and best practices.

The first step is to audit existing packing procedures. This involves evaluating current packing materials, techniques, and workflows to identify areas for improvement. By scrutinising each stage of the packing process, businesses can pinpoint inefficiencies and compliance gaps that require attention.

Subsequently, formulating a strategic plan for implementing changes is crucial. This plan should prioritise areas of improvement based on audit findings and define specific objectives for packing optimisation. For instance, companies may transition to sustainable packaging materials or invest in new technologies to enhance efficiency.

Training staff on new packing protocols and practices is another essential step. Employees should be equipped with the knowledge and skills to implement optimised packing strategies effectively. Regular training sessions can ensure that all team members are up to date with the latest regulations and best practices.

Finally, establishing metrics to gauge the success of the packing overhaul is essential. By tracking key performance indicators such as clearance times and cost savings, businesses can assess the impact of their changes and make data-driven decisions for further optimisation.

How to Train Teams on UK-Specific Protocols?

Training teams on UK-specific packing protocols is crucial for ensuring a consistent application of best practices and compliance with local regulations. Educating staff on the intricacies of UK customs requirements and packing techniques can reduce errors and enhance overall efficiency.

The training programme should begin with an overview of UK customs regulations, including key requirements for packaging and labelling. This foundational knowledge helps employees comprehend the importance of compliance and its implications on the clearance process.

Next, practical training sessions should focus on packing techniques that align with UK standards. Employees should learn to select appropriate packing materials, secure items properly, and adhere to weight-distribution guidelines. Hands-on workshops can reinforce these concepts, allowing team members to practise their skills in real-world scenarios.

Moreover, incorporating regular refresher courses can help keep employees informed of any changes in regulations or best practices. This commitment to continuous learning fosters a culture of accountability and excellence within the organisation. By investing in comprehensive training, UK businesses can ensure their packing teams are well-equipped to optimise packing processes.

What Common Pitfalls Should Be Avoided in the UK?

Neglecting packing optimisation in UK settings can lead to various risks and challenges that adversely affect business operations. One significant risk is the heightened risk of customs delays, which can tarnish a company’s reputation and efficiency. Non-compliance with UK regulations can result in fines, damaged goods, and lost customers.

Another common pitfall is overlooking the significance of weight distribution during packing. Poorly balanced loads can cause product damage and transport hazards, ultimately affecting customer satisfaction. Companies should ensure their packing processes prioritise safety and compliance with UK health and safety regulations.

Furthermore, failing to utilise the latest technologies can hinder efficiency and productivity. Companies that neglect to adopt modern packing solutions may struggle to keep pace with competitors, resulting in lost market share. Staying informed about emerging packaging technologies and practices is critical for maintaining a competitive edge in the UK market.

Finally, inadequate training for packing teams can contribute to ongoing challenges. When employees lack the skills and knowledge to optimise packing processes, businesses may experience inefficiencies and errors. Investing in comprehensive training and fostering a culture of continuous improvement can help mitigate these risks, ensuring smoother operations and better outcomes in UK logistics.

Frequently Asked Questions

What Is Packing Optimisation?

Packing optimisation is the efficient arrangement and securing of goods for transport to reduce costs, comply with regulations, and enhance safety during transit.

Why Is Packing Crucial for UK Logistics?

Packing is vital to UK logistics, as it ensures compliance with customs regulations, reduces shipping costs, and protects products during transit.

How Can Businesses Enhance Packing Efficiency?

Businesses can enhance packing efficiency by employing standardised protocols, adopting automation technologies, and providing training for packing teams.

What Materials Are Recommended for Sustainable Packing?

Recommended materials for sustainable packing include recyclable cardboard, biodegradable packing peanuts, and moisture-resistant films that bolster protection.

How Does Technology Influence Packing Processes?

Technology impacts packing processes by automating tasks, optimising space utilisation, and improving regulatory compliance, thereby increasing efficiency.

What Are the Benefits of Weight Distribution in Packing?

Proper weight distribution in packing ensures safety during transport, minimises product damage, and enhances compliance with UK health and safety regulations.

How Can Companies Measure Packing Success?

Companies can measure packing success by tracking key performance indicators such as clearance speed, cost savings, and customer satisfaction ratings.

What Are Common Packing Pitfalls to Avoid?

Common packing pitfalls include inadequate labelling, poor weight distribution, neglecting compliance with regulations, and insufficient training for packing teams.

How Does Packing Optimisation Affect Customer Satisfaction?

Packing optimisation affects customer satisfaction by ensuring timely deliveries, reducing product damage, and enhancing the overall quality of the customer experience.

What Steps Should Businesses Take to Implement Packing Changes?

Businesses should conduct audits of current practices, develop strategic plans, train staff on new protocols, and establish metrics to measure the success of optimisation.