Comprehensive Insight into the Risks Associated with Lifting Heavy Items

Identifying Common Lifting-Related Injuries

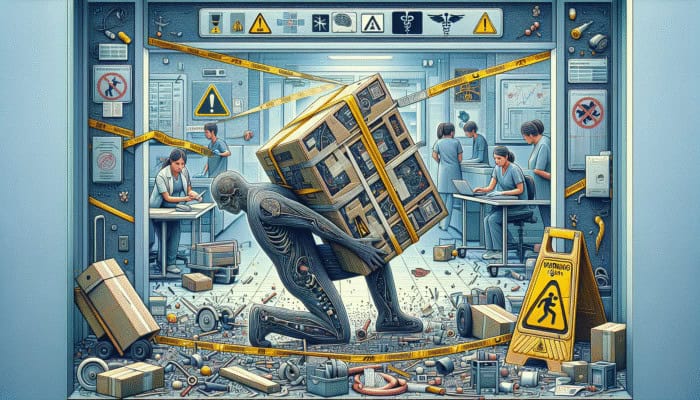

Safe Lifting Techniques for Clearance Items: Improperly lifting heavy clearance items can lead to various injuries, the most prevalent being strains and sprains. Such injuries often occur when individuals attempt to lift objects that exceed their physical capabilities or neglect proper lifting techniques. For example, lifting a heavy box without bending the knees not only exerts unnecessary stress on the back but can also result in acute injuries, such as muscle tears, or chronic conditions like herniated discs. It is essential to understand these risks to prevent injury effectively.

The repercussions of these injuries extend far beyond physical discomfort, significantly affecting an individual’s daily life. Simple activities, like bending down to tie shoelaces or picking up children, can transform into daunting challenges. Statistics indicate that back injuries constitute a substantial percentage of workplace injuries, often resulting in prolonged absences and escalating healthcare costs. Consequently, comprehending lifting mechanics and adhering to proper techniques minimises these risks and ensures a safer working environment.

The risk of injury increases significantly in specific work settings, particularly in warehouses or retail spaces where heavy clearance items are frequently handled. Employees lacking training in safe lifting techniques are particularly vulnerable. This underscores the need for personal awareness and comprehensive training programmes to educate employees on safe lifting practices, ultimately fostering a safety culture and responsibility in handling heavy items.

Long-Term Health Consequences of Improper Lifting

The consequences of improper lifting extend beyond immediate injuries to include long-term health issues that can lead to chronic pain and disabilities, severely impacting one’s quality of life. For instance, repetitive strain injuries resulting from poor lifting techniques can manifest as chronic back pain, arthritis, or sciatica, which may drastically hinder mobility and overall well-being. It is crucial to understand these risks to protect oneself effectively.

Additionally, the psychological impacts of chronic pain should not be underestimated. Individuals enduring persistent pain may face heightened levels of anxiety and depression, contributing to a diminished quality of life. Such individuals may become increasingly inactive, exacerbating health issues and creating a detrimental cycle of decline. Recognition of these potential outcomes is essential for both individuals and employers to promote better health and safety practices.

The implications can be severe in the workplace, leading to increased absenteeism and decreased productivity. Employers may encounter rising compensation claims and medical costs associated with lifting injuries, which strain resources. By investing in employee education regarding the significance of adhering to safe lifting techniques for clearance items, organisations can improve individual health outcomes and enhance overall workplace efficiency and morale.

Effective Strategies for Preventing Lifting Injuries

Preventing lifting-related injuries begins with awareness and preparation. One effective strategy is cultivating a workplace safety culture, encouraging employees to pause and assess before lifting. This involves evaluating the load and seeking help when necessary. Implementing simple practices, such as ensuring that the lifting area is free from obstacles and distractions, can significantly mitigate risks associated with lifting.

Employers should establish clear guidelines on lifting techniques and ensure that all employees receive training on safe handling practices. Regular safety meetings or refresher courses on proper lifting methods can reinforce these strategies, creating a knowledgeable workforce. Additionally, visual aids and reminders in common lifting areas can serve as constant prompts to keep safe practices at the forefront of employees’ minds.

Another effective prevention strategy involves integrating ergonomic solutions into the workplace. This may include adjusting shelving for better access to clearance items, employing carts or dollies to transport heavy loads, and ensuring adequate lighting in lifting areas. These enhancements facilitate safe lifting practices and foster a healthier overall work environment, positively impacting employee satisfaction and well-being.

Mastering Proper Lifting Techniques for Safety

Mastering the correct lifting techniques is vital for reducing the risk of injury when handling heavy clearance items. First and foremost, always plan the lift by assessing the object’s weight and determining whether it is necessary to lift it alone or if assistance is needed. This preparation can make a significant difference in safely executing the lift.

When preparing to lift, position your feet shoulder-width apart to maintain balance. Bend at the hips and knees, ensuring your back remains straight and your chest is lifted. This posture enables your inherently stronger leg muscles to perform the lifting rather than placing undue strain on your back. Additionally, engaging your core muscles can provide extra support during the lift, enhancing stability and control.

While lifting, keep the item close to your body and maintain a firm grip to prevent slipping. Avoid twisting your torso while lifting; pivot your feet to change direction as needed. When lowering the object, use the same techniques: bend your knees and keep your back straight. Proper training in these methods can significantly enhance safety and efficiency when dealing with heavy clearance items, fostering a safer work environment and preventing injuries.

Essential Preparations for Safe Lifting Practices

Thoroughly Assessing the Load Before Lifting

Before attempting to lift any clearance items, it is imperative to assess the load thoroughly. Understanding the weight and dimensions of the item can dramatically influence your lifting technique and overall safety. Start by inspecting for labels or markings that provide insight into the item’s weight. If no weight is indicated, performing a preliminary test lift is wise by gently lifting one corner of the object to gauge its heaviness.

Consider the load’s centre of gravity as well; top-heavy items can be particularly hazardous and may require additional caution when lifting. If an item appears excessively heavy or awkwardly shaped, do not hesitate to enlist help or utilise equipment specifically designed for heavy lifting. Being mindful of the load’s characteristics allows you to devise a safe and effective approach to lifting, thus preventing risks associated with improper lifting techniques.

Moreover, it is crucial to assess your physical limitations before attempting to lift heavy items. Evaluate your strength and stamina; if you feel fatigued or unwell, postpone the lift or seek assistance. Fostering a culture of open communication regarding lifting capabilities and load assessments can significantly enhance safety in environments where clearance items are frequently handled, ensuring that all employees feel supported and informed.

Selecting the Appropriate Lifting Equipment

Choosing the right equipment can greatly facilitate the safe lifting of clearance items. For lighter loads, tools such as trolleys or carts can be invaluable, helping to reduce physical strain on the body while allowing for the efficient transport of multiple items. When dealing with heavier loads, consider using lifting belts or harnesses, which provide additional support to the lower back during lifts, enhancing overall safety.

For particularly bulky items, mechanical aids like forklifts or pallet jacks may be necessary to prevent injury. It is critical to familiarise yourself with the operation of this equipment; improper use can lead to accidents and injuries. Employers should consider providing comprehensive training sessions on the proper usage of lifting equipment and ensure that these tools are readily accessible to all workers.

In addition to physical tools, incorporating ergonomic equipment designed to enhance lifting safety should also be a priority. Adjustable height workstations and anti-fatigue mats can help create a more conducive lifting environment, contributing to overall health and safety while managing clearance items effectively and efficiently.

Creating a Safe Lifting Environment

Establishing a safe lifting environment is paramount in preventing accidents and injuries. Before lifting, ensure that the area is free of clutter and obstructions. A clean workspace allows for better visibility and ease of movement, significantly reducing the risk of trips and falls during lifting. This attention to detail can greatly enhance safety.

Consider the layout of your workspace as well. Ensure sufficient space for manoeuvring heavy items and adequate lighting for clear visibility. Position items in areas that are easily accessible, minimising the need for awkward reaching or stretching that can lead to injuries. By creating a thoughtful and organised work environment, you promote a culture of safety and efficiency.

Another critical aspect of creating a safe environment involves effective communication. If lifting in a team setting, ensure all members know the lifting plans and their designated roles. Establishing clear signals or commands can help synchronise efforts, significantly reducing the chance of accidents or miscommunication during the lift. This proactive approach fosters teamwork and enhances safety.

Strategically Planning the Lifting Route

Before lifting, meticulously plan your lifting route to ensure maximum safety. Identify the safest path for transporting clearance items, ensuring it is free from obstacles that could hinder movement. This includes checking for loose cables, uneven flooring, or any potential tripping hazards that could pose a risk during the lift.

Consider the visibility along the route; it is essential to ensure you can see where you are going while lifting. If the load obstructs your view, ask a colleague to guide you along the path. This collaborative approach enhances safety and nurtures teamwork, making the lifting process more efficient.

Additionally, be mindful of doors, narrow passageways, or stairs. These areas can present significant challenges and may require additional strategies, such as using ramps for wheeled equipment. By planning the lifting route effectively, you can eliminate unnecessary risks and navigate the environment more safely, ensuring that lifting tasks are completed without incident.

Employing Proper Lifting Techniques for Safety

The correct lifting techniques are vital for ensuring safety when handling clearance items. Start by positioning yourself correctly; place your feet shoulder-width apart to maintain balance and stability. Bend your knees while keeping your back straight as you prepare to lift the item, drawing on the strength of your legs rather than your back to perform the lift.

As you lift, engage your core muscles for additional support. Keeping the load close to your body is critical, as this reduces strain on your back and allows for better control over the item. Always lift smoothly and steadily, avoiding sudden movements or jerks that could lead to injury or loss of balance.

When lowering the item, follow the same principles. Maintain a straight back, keep your knees bent, and lower the item carefully to the ground. This method safeguards your back and promotes better handling of heavy clearance items, ensuring your lifting efforts are safe and effective.

Optimising Lifting Techniques for Maximum Safety

Maintaining Correct Posture During Lifting

Establishing correct posture is foundational to executing safe lifting techniques effectively. When preparing to lift an object, stand close to the item with your feet shoulder-width apart. This position provides a stable base and allows for better leverage during the lift, enhancing safety and efficiency.

Bend at the knees, not the waist, ensuring that your back remains straight and your chest is lifted. This alignment is vital; it shifts the load from your back to your legs, which are significantly stronger and capable of handling the weight more effectively. Engaging your core muscles will also provide additional stability, reducing the risk of injury during the lift.

While maintaining this posture, grasp the item firmly, ensuring your grip is secure. Avoid twisting your body while lifting; pivot with your feet if you need to change direction. Proper posture is crucial not just during the lift but also in how you carry and lower the load, reinforcing the importance of maintaining a straight back and bent knees throughout the entire lifting process.

Understanding Lifting Mechanics for Safe Practices

Understanding the mechanics of lifting is key to mastering safe lifting techniques. The primary focus should always be on using your legs to perform the lift. As previously mentioned, bending your knees engages the powerful muscles of your lower body, allowing you to lift heavier loads without straining your back or risking injury.

It is essential to lift smoothly and control. Engage your core as you initiate the lift, pushing your legs upwards while keeping the load close to your body. This technique enhances your control over the item and minimises the risk of losing your balance during the lift.

Another critical aspect of lifting mechanics is avoiding awkward angles during the lift. Ensure that your arms are positioned in a way that allows for a straight lift, thereby reducing strain on your shoulders and upper body. The combination of proper technique and mechanics can significantly decrease the likelihood of injury while handling heavy clearance items, promoting a safer working environment.

Safe Techniques for Moving and Lowering Items

Moving and lowering heavy clearance items requires just as much attention to technique as the lifting itself. When transporting an item, maintain a strong grip and keep the load as close to your body as possible. This approach increases your stability and reduces strain on your arms and back, facilitating safer handling of the item.

As you approach the area where you intend to lower the item, carefully assess your surroundings to ensure a safe descent. Confirm that the surface is stable and free of obstructions. To lower the load, bend at the knees while keeping your back straight. This method allows for a controlled descent, preventing the item from dropping suddenly, which can lead to injuries or accidents.

Engaging your core throughout this process helps maintain balance and control. If you need to shift the load or adjust your grip, do so smoothly and deliberately, avoiding sudden movements that could compromise your safety. By practising these moving and lowering techniques consistently, you can significantly minimise the risk of injury and ensure the safe handling of clearance items.

Guidelines for Team Lifting

Prioritising Communication in Team Lifting

Effective communication is paramount when lifting heavy clearance items as a team. Before attempting a lift, all team members must discuss the plan. This includes identifying who will lead the lift, how many people will be involved, and any specific roles or responsibilities assigned to each team member.

Establishing verbal cues can significantly enhance coordination and prevent accidents during the lifting process. For example, commands such as “lift” or “lower” allow everyone to move in unison, greatly reducing the risk of miscommunication or sudden movements that could lead to injury. This proactive approach fosters a safer lifting environment.

Moreover, team members should feel empowered to voice concerns. If anyone feels that the load is too heavy or awkward to lift safely, it is crucial to halt the operation immediately and reassess the situation. Cultivating a culture of open communication around lifting promotes safety and ensures that all team members are aligned in their efforts.

Coordinating Movements for Effective Team Lifting

Synchronising movements is essential when engaging in team lifting. Each member must know their timing and positioning to avoid jerking or twisting motions that could result in injury. Practising the lifting process beforehand can help ensure everyone is familiar with the rhythm and coordination needed for a smooth operation.

Team members should count down together to initiate the lift simultaneously when preparing to lift. This collective action fosters a sense of unity and shared responsibility, enhancing teamwork while reducing the risk of accidents during the lift. This collaborative approach is fundamental for safe lifting practices.

Maintaining eye contact during the lift can further ensure that all participants are working in sync. If one person needs to adjust their grip or change direction, a simple glance or nod can facilitate a coordinated response, ensuring everyone knows the plan. By emphasising the importance of teamwork in lifting, you can promote a safer environment while enhancing the overall efficiency of the lifting process.

Sharing the Load Wisely Among Team Members

Sharing the load among team members is crucial when lifting heavy clearance items. This approach reduces the strain on individual participants and enhances overall safety during the lift. When dividing the load, consider each person’s strength and physical capabilities, ensuring everyone is comfortable with their weight.

A balanced approach is essential; position team members evenly around the load to distribute weight effectively. This balance improves stability during the lift and allows for smoother, more coordinated movement, reducing the likelihood of accidents. This strategic method is vital for safe lifting practices.

If an item is particularly cumbersome, consider using additional tools, such as straps or slings, to assist in sharing the load. These tools support the weight and enhance grip and control during the lift, ensuring safety for all team members. Ultimately, by prioritising the sharing of the load, you foster a safer lifting environment while encouraging teamwork and collaboration among staff.

Special Considerations When Handling Clearance Items

Addressing the Challenges of Irregularly Shaped Items

Handling clearance items with irregular shapes can present unique challenges in lifting and transport. These items often lack designated grips or a stable centre of gravity, which increases the potential for accidents. When dealing with such items, adopting a careful and strategic approach to lifting is crucial to ensure safety.

Examine the item closely to identify the best points to grasp for lifting. Use additional equipment, such as blankets or pads, to improve grip and protect the item’s surface, especially for fragile clearance items. This thoughtful consideration is essential to prevent damage during handling.

When lifting, ensure a clear view of the item and the path ahead. If the irregular shape obstructs your vision, consider employing a spotter to assist in navigating potential hazards. By remaining vigilant and adopting a cautious approach, you can safely handle items with irregular shapes while reducing the risk of injury and ensuring a secure lifting process.

Safely Handling Fragile Items

When handling fragile clearance items, the stakes are higher; not only is there a risk of personal injury, but the items themselves may also be damaged. To lift fragile items safely, meticulous planning and execution are required. Begin by assessing the item’s fragility and the appropriate handling techniques.

Utilise padded gloves to improve grip and reduce the likelihood of dropping the item. Consider using a cushioned carrying case or box for extra protection if the item is particularly delicate. When lifting, adopt a slow, deliberate motion, ensuring that all colleagues know the delicate nature of the lifted item. This communication is vital in ensuring everyone proceeds with caution.

Communicating the fragility of the item to all team members involved is essential. Everyone should understand the importance of handling the item carefully and be aware of the potential consequences of mishandling. By prioritising safety and open communication, you can effectively manage the risks of lifting fragile clearance items, protecting individuals and valuable assets.

Strategies for Lifting Heavy or Bulky Items Safely

Managing heavy or bulky clearance items often requires additional strategies to ensure safe lifting practices. First and foremost, always assess the weight and size of the item before attempting to lift it. If it appears excessively heavy or unwieldy, do not hesitate to ask for assistance from colleagues or utilise appropriate lifting equipment designed for such loads.

Utilising suitable lifting equipment, such as forklifts or hoists, can significantly reduce the physical strain of handling heavy items. Familiarity with the operation of this equipment is critical; ensure that all operators have received adequate training to operate these tools safely and prevent accidents.

When lifting heavy items manually, maintain proper form throughout the process. As with any lifting, remember to engage your legs and core while keeping the load close to your body for better control and balance. If the item is too bulky to lift directly, consider breaking it down into smaller, more manageable parts to promote safety. By taking these precautions, you can foster a safer lifting environment when dealing with heavy and bulky clearance items.

The Importance of Training and Education in Safe Lifting

Recognising the Significance of Training

Anyone involved in handling clearance items must undergo ongoing training in safe lifting techniques. Regular training sessions ensure that employees remain aware of best practices and the latest safety protocols, reducing the likelihood of injuries. This knowledge not only protects individuals but also promotes a culture of safety within the workplace.

Investing in comprehensive training programmes significantly reduces the likelihood of injuries and associated costs. Employees who understand lifting mechanics and the importance of proper techniques are less prone to experiencing acute injuries or chronic pain over time. Additionally, ongoing education reinforces the significance of safety in everyday operations, benefiting both individuals and the organisation.

Employers should consider implementing theoretical and practical training, allowing employees to gain hands-on experience with safe lifting techniques. Continuous education helps to instil confidence in workers, enabling them to handle clearance items effectively and safely, ultimately contributing to a safer workplace environment.

Identifying Workshops and Courses for Safe Lifting

Finding workshops and courses focused on safe lifting practices is essential for organisations committed to employee safety. Many local health and safety organisations offer training sessions that cover a range of lifting techniques and equipment usage. These workshops typically provide a mix of theoretical knowledge and practical demonstrations, ensuring participants can effectively apply what they learn in real-world scenarios.

Employers should seek out reputable training providers and encourage employees to attend these sessions. Consider hosting in-house training sessions tailored to address specific challenges faced within your organisation, such as handling unique clearance items. Tailored workshops can directly address the needs of your workforce, enhancing the effectiveness of the training and ensuring its relevance.

Regularly updating training materials and offering refresher courses can also help reinforce safe lifting practices. This ongoing commitment to education enhances safety and demonstrates an organisation’s dedication to employee well-being and professional development.

Reinforcing Safe Lifting Practices Across the Workplace

Reinforcing safe lifting practices among staff and volunteers is vital to maintaining a safety culture. Regular safety meetings can serve as a platform for discussing best practices and addressing any concerns related to lifting techniques. These meetings can also incorporate practical demonstrations to remind employees of the correct methods and techniques for lifting safely and effectively.

Additionally, visual reminders in common lifting areas can keep safe practices at the forefront of employees’ minds. Posters showcasing correct lifting postures or tips for assessing loads can serve as valuable reference points, helping to reinforce training and promote awareness of safe practices.

Encouraging peer-to-peer observation and feedback can also reinforce safe practices. Empowering employees to identify unsafe behaviours and share constructive feedback creates a supportive environment that prioritises safety. This collaborative approach promotes safe lifting techniques and fosters a culture of accountability among staff, contributing to overall workplace safety.

Understanding Legal and Safety Regulations for Lifting

Ensuring Compliance with Health and Safety Laws

Understanding the legal requirements for safe lifting practices is essential for employees and employers. In the UK, the Health and Safety at Work Act 1974 imposes a duty on employers to ensure, as far as is reasonably practicable, the health and safety of their employees while at work. This includes providing adequate training and information on safe lifting techniques, fostering a workplace safety culture.

Employers must also be aware of specific regulations, such as the Manual Handling Operations Regulations 1992, which outline safe manual handling principles. These regulations emphasise assessing the risks associated with lifting operations and implementing appropriate controls to mitigate those risks effectively. Compliance with these regulations is crucial for maintaining a safe work environment.

Failure to comply with these legal requirements can lead to significant consequences, including fines and legal actions against the organisation. Organisations can protect their employees and avoid legal repercussions by prioritising compliance and maintaining a proactive approach to safety, ensuring a safer workplace for everyone involved.

Upholding Health and Safety Standards in Lifting Practices

Meeting health and safety standards when handling clearance items is critical to ensuring employee safety. Regular audits and assessments of lifting practices can help identify potential hazards and areas for improvement. Compliance with established safety standards, such as those outlined by the Health and Safety Executive (HSE), is essential for creating a safe work environment for all employees.

In addition to compliance, organisations should implement a risk assessment process specific to lifting operations. This process should evaluate the potential risks associated with different clearance items and establish protocols for managing those risks effectively. By prioritising health and safety standards, organisations can enhance their overall lifting practices and cultivate a culture of safety in the workplace.

This proactive approach protects employees and contributes to increased productivity and morale within the workplace, fostering a positive and safe work environment for all.

Implementing Effective Incident Reporting Procedures

A clear procedure for reporting lifting-related incidents and injuries is vital for maintaining a safe lifting environment. All employees should be well-informed of the protocol for reporting accidents, near misses, or any unsafe practices they observe. This transparency allows organisations to investigate incidents thoroughly and identify areas for improvement in safety practices.

Encouraging a culture of openness around reporting incidents can help destigmatise the process and promote accountability. Employees should feel empowered to report concerns without fear of retribution, knowing that their input can lead to positive changes in safety practices and ensure a safer workplace for everyone.

Following an incident, organisations should thoroughly investigate the root causes and implement corrective actions. This proactive approach enhances safety and demonstrates a commitment to continuous improvement in lifting practices, contributing to a safer work environment.

Training and Certification for Compliance

Training and certification are essential components of ensuring compliance with lifting safety regulations. Many organisations offer accredited training courses on safe lifting techniques and manual handling practices. Ensuring that employees receive certification demonstrates a commitment to their safety and well-being, enhancing workplace safety.

Employers should regularly review training records to ensure all employees have completed the necessary courses. Offering refresher training sessions can also help reinforce safe practices and keep employees informed of any regulations or best practices changes. This ongoing commitment to training protects employees and contributes to overall workplace efficiency and morale.

By prioritising training and certification, organisations can significantly reduce the risk of lifting-related injuries and create a safer work environment for everyone. This investment in employee safety pays dividends in terms of reduced injuries and improved workplace productivity.

Conducting Comprehensive Risk Assessments

Conducting thorough risk assessments is crucial for identifying and mitigating hazards associated with lifting operations. A risk assessment should evaluate the specific clearance items being handled, the lifting techniques employed, and the overall environment in which lifting occurs. This comprehensive analysis is essential for ensuring safety during the lifting process.

When assessing risks, consider factors such as the weight and size of items, the physical capabilities of employees, and any environmental hazards that may be present. Engaging employees in the risk assessment process can provide valuable insights and foster a collaborative approach to safety. Organisations can enhance safety outcomes and promote a culture of shared responsibility by involving workers in this critical process.

Following the assessment, develop a comprehensive action plan to address identified risks. This may involve providing additional training, implementing new lifting equipment, or redesigning workspaces to improve safety. Organisations can create a safer lifting environment and enhance overall workplace well-being by prioritising risk assessment and proactive measures.

Maintaining Safe Lifting Habits for Long-Term Safety

Regularly Practising Safe Lifting Techniques

Regularly practising safe lifting techniques is essential for maintaining proficiency and reducing the risk of injury over time. As with any skill, the more natural and automatic safe lifting becomes, the more you practice. Encourage employees to integrate lifting exercises into their daily routines, reinforcing the principles of proper lifting techniques and making them second nature.

Employers should consider organising regular safety drills or workshops to provide staff with hands-on practice. This type of training reinforces proper techniques and promotes a culture of safety and accountability within the workplace. By creating practice opportunities, organisations can ensure that safe lifting becomes ingrained in their workplace culture.

Regular practice helps employees stay vigilant about safe lifting techniques, significantly reducing the likelihood of accidents and injuries. Organisations can promote a culture of safety and well-being among staff by fostering an environment that prioritises continuous learning and improvement.

Monitoring Lifting Practices and Providing Constructive Feedback

Monitoring lifting practices and providing constructive feedback are essential for safe lifting habits. Supervisors should regularly observe employees during lifting tasks, offering immediate corrections and reinforcement of safe techniques. This real-time monitoring allows for immediate adjustments and helps reinforce safe lifting behaviours.

Encouraging peer-to-peer feedback can also enhance safety. Colleagues should feel empowered to share insights and observations regarding each other’s lifting techniques. This collaborative approach fosters a sense of accountability and promotes a safer environment, as workers support one another in adhering to safe lifting practices.

Regularly reviewing lifting practices during safety meetings can help identify trends or common issues requiring additional training or procedure adjustments. By maintaining an ongoing dialogue about lifting safety and creating a safer workplace, organisations can continually improve their practices and minimise risks.

Prioritising Training and Education for Safety

Ongoing training and education are vital for reinforcing safe lifting practices and awareness among employees. Regularly scheduled training sessions ensure that workers remain informed about best practices and any updates to safety regulations. This commitment to education not only protects employees but also fosters a culture of safety within the workplace.

To cater to different learning styles, employers should consider incorporating various training methods, such as hands-on workshops, e-learning modules, and safety seminars. This variety keeps training engaging and allows employees to learn in ways that suit their preferences, enhancing retention and application of safe lifting practices.

By prioritising continuous education, organisations can ensure that safe lifting techniques remain a central focus of safety culture. The investment in training pays dividends in terms of reduced injuries, increased morale, and a more effective workforce overall.

Utilising Proper Equipment for Safe Lifting

Utilising appropriate lifting equipment and tools is crucial for preventing injuries and ensuring safety in the workplace. Employers should ensure that all necessary lifting equipment, such as trolleys, hoists, and lifting belts, is readily available and maintained in good working order. This accessibility is essential for promoting safe lifting practices.

Training employees on the proper use of this equipment is equally essential. Regularly scheduled inspections and maintenance of lifting tools can help identify potential issues before they become hazards. By promoting proper equipment, organisations can significantly reduce the risks associated with manual lifting and enhance safety and efficiency in handling clearance items.

Frequently Asked Questions About Safe Lifting

What are the key safe lifting techniques for clearance items?

Safe lifting techniques for clearance items encompass assessing the load, maintaining a stable posture with bent knees, keeping the load close to your body, and utilising your legs for lifting rather than relying on your back. These principles are fundamental to safe lifting practices.

Why is it crucial to use proper lifting techniques?

Proper lifting techniques are essential to prevent injuries, such as strains and sprains, and safeguard long-term health. They ensure you can perform daily tasks without chronic pain or discomfort. This emphasis on safe practices is vital for overall well-being.

What should I do if I feel uncomfortable lifting a heavy item?

If you feel uncomfortable lifting a heavy item, seeking assistance or using lifting equipment is crucial. Please do not attempt to lift it alone, as this can lead to serious injury. Always prioritise safety and communicate your concerns.

How frequently should lifting training be conducted in the workplace?

Lifting training should be conducted regularly, ideally annually or whenever new employees are hired, to ensure everyone remains informed about safe lifting practices and any updates to regulations or techniques. Consistent training is key to maintaining a safe workplace.

Which equipment can assist with lifting heavy items?

Equipment such as trolleys, hoists, and lifting belts can be invaluable in lifting heavy items. They reduce physical strain and enhance safety during lifting. Proper use of these tools is critical for effective lifting.

How can I create a safe lifting environment?

To create a safe lifting environment, ensure the area is clear of obstructions, provide adequate lighting, and maintain effective communication with team members during lifts. These practices contribute to a safer and more efficient lifting experience.

What are the legal requirements for lifting safety in the UK?

In the UK, the Health and Safety at Work Act 1974 mandates that employers ensure employees’ health and safety, including training on safe lifting techniques and adhering to established safety protocols.

How can I assess the weight of an item before lifting?

You can assess an item’s weight by checking for labels or markings, performing a preliminary test lift, or using scales if available to evaluate whether it is safe to lift. This assessment is crucial for preventing injuries.

What should I do if an injury occurs while lifting?

If an injury occurs while lifting, cease all lifting activities immediately, assess the injury, seek medical attention if necessary, and report the incident according to workplace protocols to ensure proper follow-up and support.

Why is teamwork important when lifting heavy items?

Teamwork is vital when lifting heavy items. It allows for shared responsibility, reduces individual strain, and enhances safety through coordinated movements and effective communication among team members. This collaborative approach promotes a safer lifting experience.